Interview with Mario Conserva, general secretary of FACE (Federation of Aluminium Consumers in Europe), editor of A&L magazine (Alluminio&Leghe), president of METEF (world-leading exhibition dedicated to aluminium).

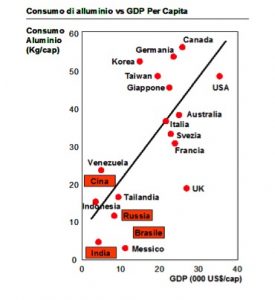

After steel, aluminium is the most widely used material in world. In 2019, the world’s production of primary aluminium (obtained from bauxite starting mineral) was just over 64 million tones. To give a more precise idea of the volume, in 1950 we were not even at 5 million tones.

The industry uses it for an endless number of products, from simple beverage containers to car frames. But now it’s under threat. Chinese semi-finished sold below cost products are invading the market, creating serious damage due to unfair competitiveness towards aluminium operators in other countries.

What’s more, the effects of Coronavirus are leading to a production accumulation of Chinese primary metal which is notably detrimental to the environment, because it is produced using coal energy, which has a high carbon footprint.

But let us hear in this regard the voice of an authoritative specialist, Mario Conserva, secretary-general of FACE (Federation of Aluminium Consumers in Europe) which is based in Brussels and represents the interests of aluminium processors and consumers in Europe.

Doctor Conserva, why is aluminium so environmentally friendly?

Earth’s resources are under an enormous pressure. From this point of view, the 2015 Paris Agreement on Climate Change is a significant success for the planet and its inhabitants. If we consider today the value assumed by the sustainability of an industrial material, there is no doubt that aluminium and its alloys occupy a prominent place. They are fully recyclable which means saving resources and protection of the environment). They contribute to lessening the weight of vehicles and transportations, resolve the need of food protection, and also transmit energy and characterize buildings as far as energy efficiency is concerned. Aluminium and its alloys are materials for our future, they go hand in hand with the social and industrial progress of many countries.

Let’s talk in more detail about China, which is flooding the market with low-cost products, which is dangerous for the aluminium segment. In particular, what risks do Italian and European companies face and how can they be defended?

For years, China has pursued an industrial policy aimed at creating production overcapacities in aluminium, so demolishing the European manufacturing system and thus replacing it. Some studies on the European aluminium sector, produced in 2019 by the LUISS University of Rome on behalf of FACE, showed that much of the invasion of aluminium semi-finished products in Europe is of Chinese origin, with outrageously low prices, from authentic dumping. That is why, today, we congratulate the recent resolution of the European Commission which has opened an investigation into the import of aluminium semi-finished products from China into the EU.

These are materials such as rolled and extrusions used in all segments of the industry, from construction and production of automotive, transportation, furniture, and of mechanics. Moreover, it is a segment in which Italy has a strong tradition: together with Germany we have always been productive leaders in Europe. The EU aluminium industry, which is made up of more than 90% downstream companies, is undergoing a very important transition. It must work for development and growth in critical conditions, as well as taking into account the right and sound ambitions on environmental, climate and resource conservation issues. But it must also invest heavily in digitalization, research and competitiveness to defend itself against trade distortions that threaten to undermine a system rich in technological traditions and technical knowledge.

We at FACE believe that the EU’s recent positions on the industrialization, combined with sustainability, are absolutely serious and responsible. For this reason, we believe that even more incisive and definitive measures are needed to strengthen the foundations of the aluminium chain. Anti-dumping investigations are a first step. However, interventions at the root are urgently needed, in particular the elimination of the EU duty on the import of raw aluminium. It represents a cost of more than one billion euros per year for the downstream industry. You can imagine how much research and development (R&D) on plants, alloys, technologies and products could be done by small and medium-sized companies, saving also a duty on raw materials.

Let’s go back to the environmental issues: we mentioned before that the Chinese aluminium is produced with energy which often comes from coal-fired power plants. Therefore, aluminium itself is environmentally friendly, but the way it is produced is not always so. You and FACE want to defend the clean metal, green aluminium, and prioritise its spread. How, exactly, will you achieve all these green labels?

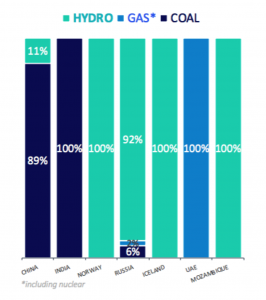

The environmental question arises in these terms: primary aluminium production requires electricity (twelve to fifteen KWh per kilogram of aluminium). In some countries, in particular China and India, energy is largely dependent on fossil fuel-powered power plants.

We could use a simple diagram to highlight the difference between one type of aluminium and another, in terms of emissions. Carbon emissions from fossil fuels clearly create huge social costs due to the impact on public health, damage to the environment and the effects on climate change. Unfortunately, over the past twenty years, most of the production capacity growth has been achieved through coal-fired and fossil fuel power plants, generating greenhouse gases four to five times more than those powered by hydroelectric power.

Essentially, not all primary aluminium is the same. Annual world production reaches sixty-five million tones: almost two-thirds come from fossil fuel-powered plants. On the other hand, many important manufacturers are engaging in R&D to fully qualify the environmental qualities of the metal. At the same time, many large end-users of aluminium would like to use Low-Carbon aluminium produced with renewable energy such as hydropower.

At FACE, we believe that the world cannot afford the growth of coal-fired aluminium production facilities. We strongly support the proposal for a control by the London Metal Exchange (LME) to certify the carbon footprint level of the primary metal put on the market, with the aim of rewarding virtuous producers. These include Rusal, which produces clean metal under the ALLOW brand, Hydro Aluminium under its own brand REDUXA, Rio Tinto under the brand RenewAl, and Alcoa marked by ECOLUM.

FACE supports the Green Aluminium, an opportunity to allow light metal users to select products and manufactured goods with a certified low carbon content and that is appropriate to their desired environmental standards, in the entire application chain.

Finally, remember that so far we’ve talked about primary aluminum, because it’s the basis of global demand for metal. But let us not forget the secondary metal, originated through recovery and recycling: virtuous product, with a very low CO2 footprint, which requires only 5% of the energy compared to the primary. In addition, recyclable indefinitely, without loss of features: a production segment in which our country has always been at the forefront of the world and FACE has always sided with it.

What are the effects of the Coronavirus on the industrial system and the aluminium value chain?

FACE, like many other associations and institutions linked to light metal, has increased its commitment and efforts at this dramatic time to protect the interests of SMEs of downstream aluminium. The entire European aluminium industry as well as all other sectors of production and beyond are affected by Covid-19 emergency, even though we must consider health problem as an absolute priority, we believe it is essential and urgent to free, as much as possible, businesses from snares and impediments, so that we can

Therefore, firstly, the competitiveness of the entire value chains must be restored and pave a path of development. Let’s say that in addition to the extraordinary support measures for difficult times – credit insurance and more liquidity, financing for investment projects, tax incentives and subsidized loans – this is the best time to realise in the aluminium’s field that strong raw material initiative I earlier mentioned: it is important that the Commission accepts the request for the immediate cancellation of the duty on the import of raw aluminium into the EU, that is on the raw material for the subsequent stages of processing and manufacturing. An intervention that means competitiveness for businesses, simple to define and strong message of the abolition of an absurd tax for processors and users on a raw material, the primary aluminium, of which EU and Italy are severely lacking.